APS Spotlight Advanced Planning Scheduling System

deliver a timely 4-simulation production planning proposal

APS The brain of production Advanced Planning Scheduling (APS)

Industrial 4.0

APS is the fundamental infrastructure system for Industrial 4.0

Implement Spotlight APS System for bettering production schedule

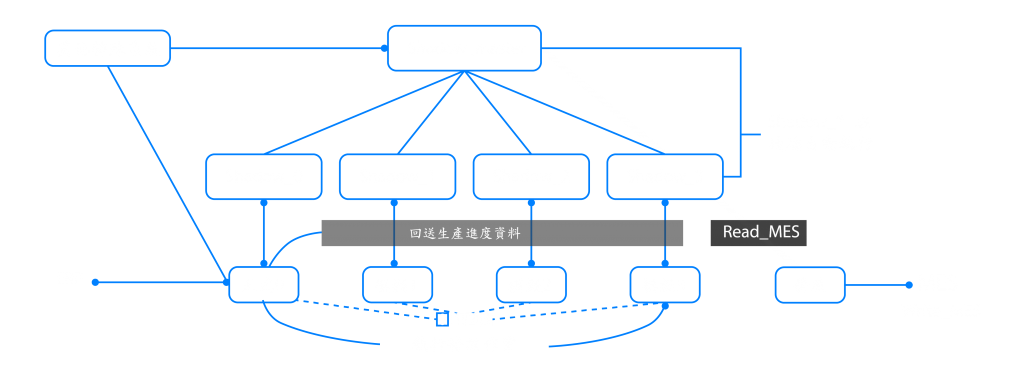

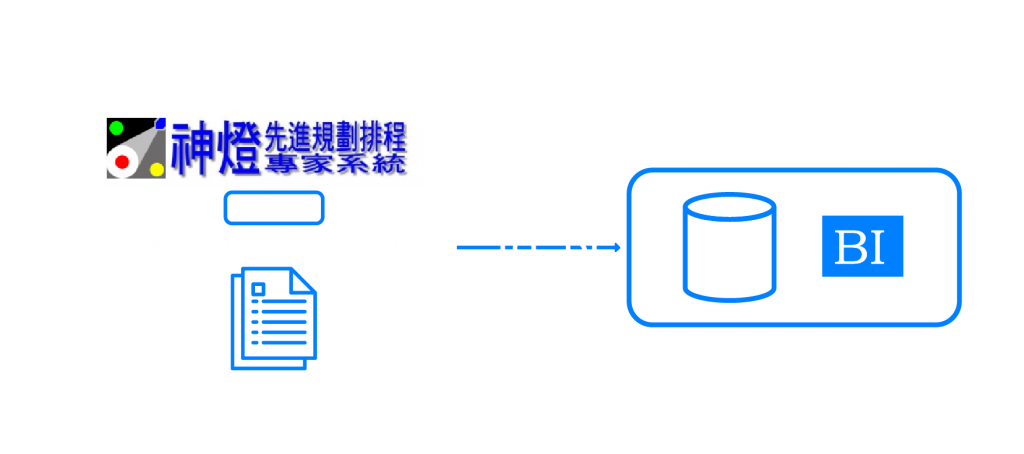

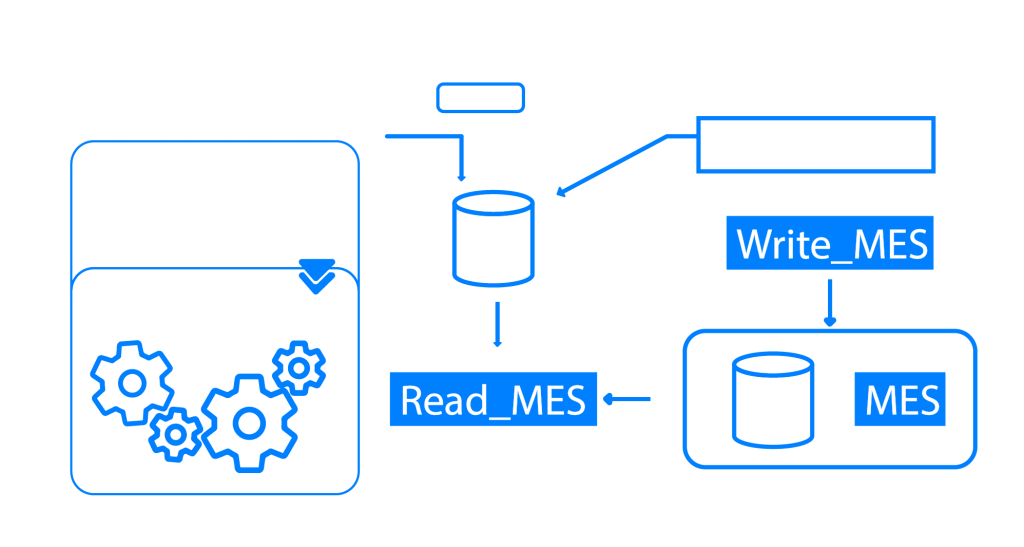

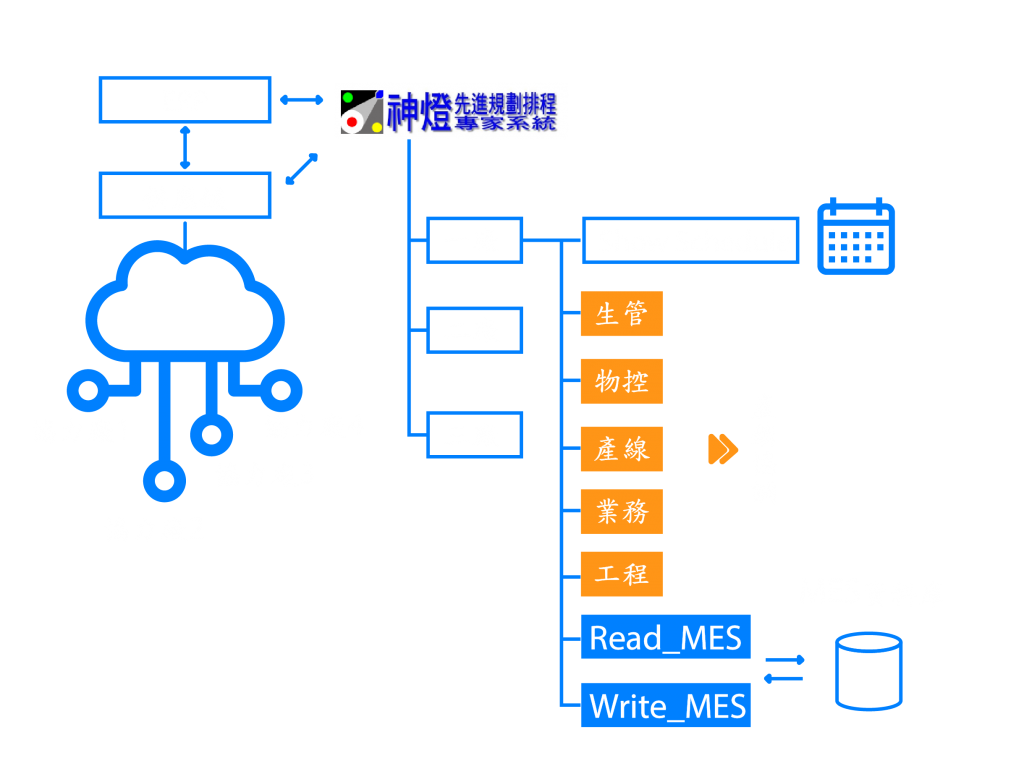

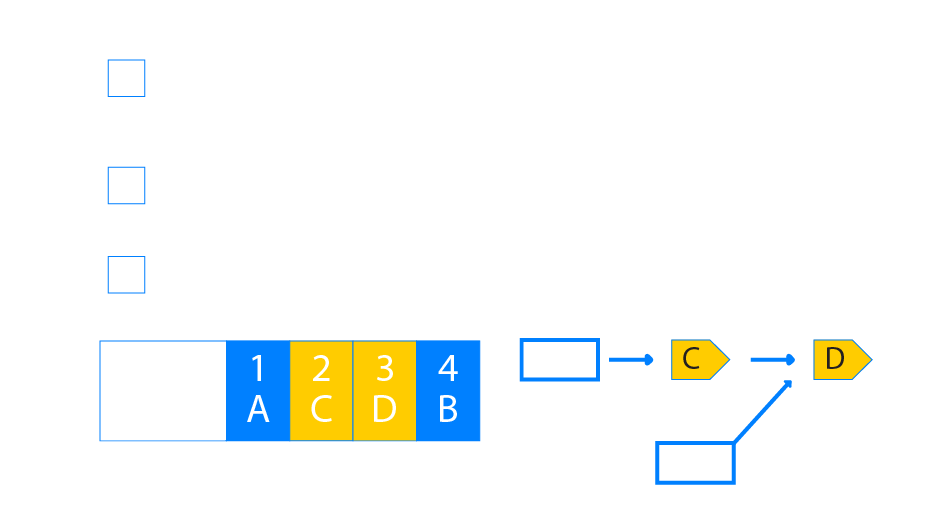

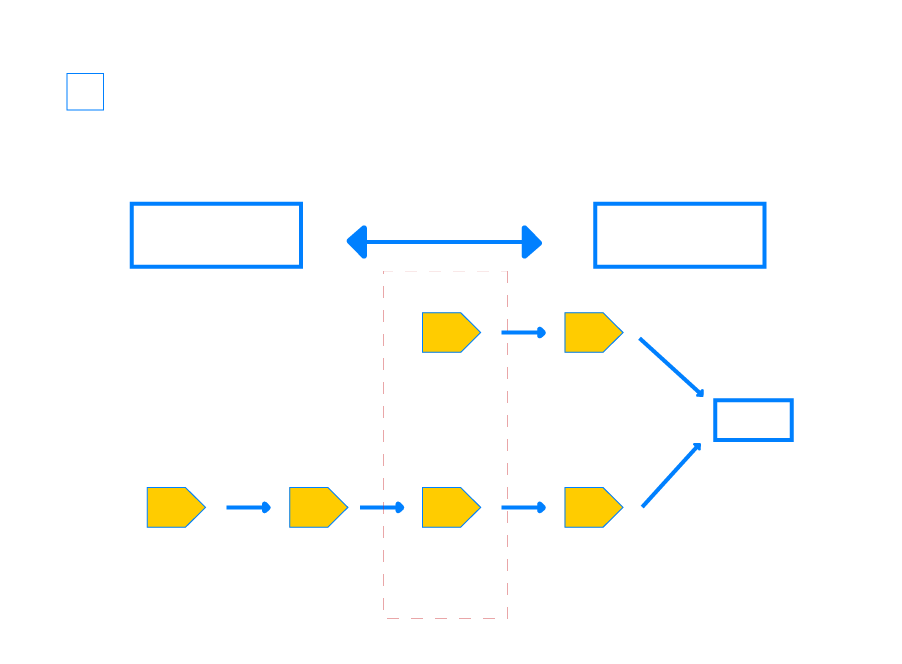

Spotlight APS System integrating both ERP purchase and warehouse data and MES production resources and designated labor forces factors, to simulate as operational four (4) assumptions, timely to generate the best scheduling options at any time, to facilitating the reconciliation between Sales and Production, turns the best outcome for planner.

Product unique customer-oriented value

1

Spotlight APS is the most advanced product adopted and proved by many listed companies, for securing the success of the application, during the Prove of Concept (POC) time, input the real data for confirming the real effectiveness and value, before make the purchase decision.

2

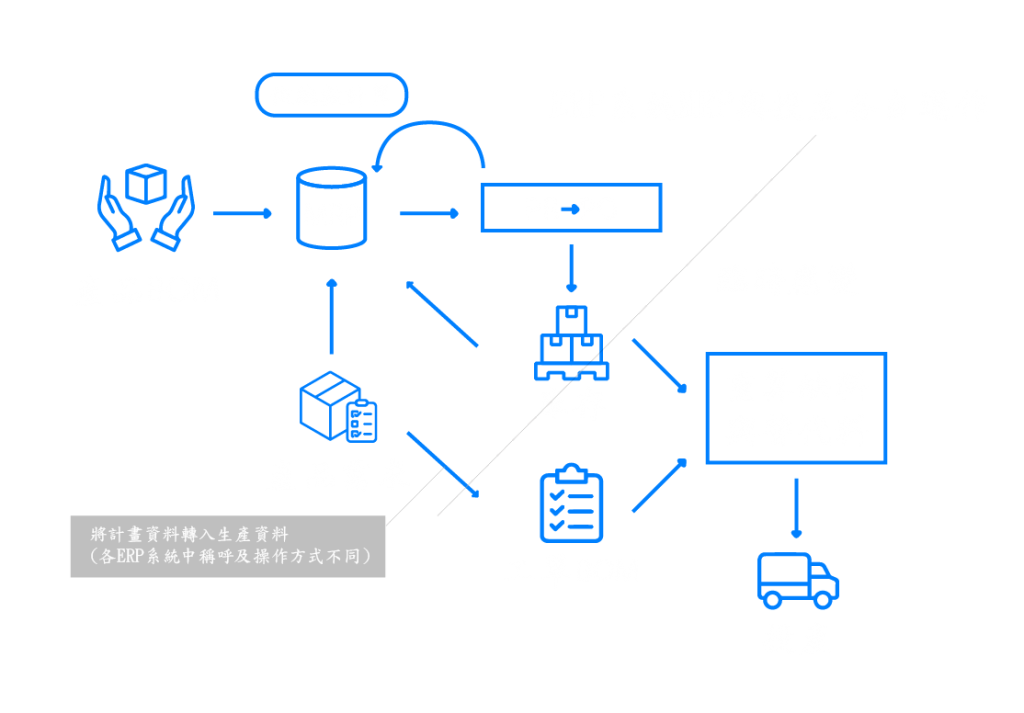

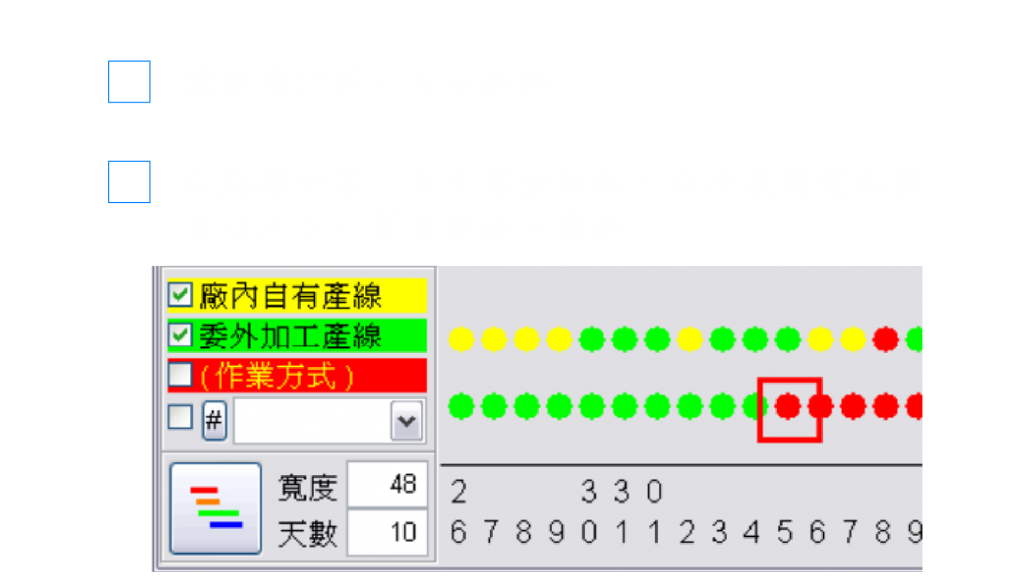

the aps include external oem or outsourced factory factor for overall calculation, without complicated routing table data, then can generate maximized planning and scheduling information. based on about 75% package-designed comprehensive functions, could shorten the implementing time, simulation outcome verification for comparing with real demand before official purchase order of aps system.

3

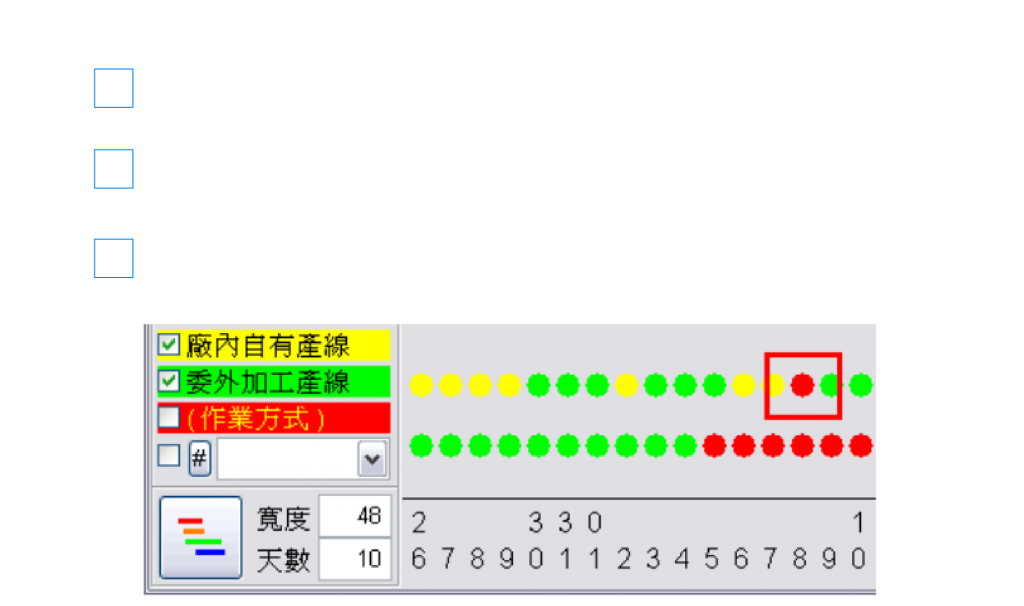

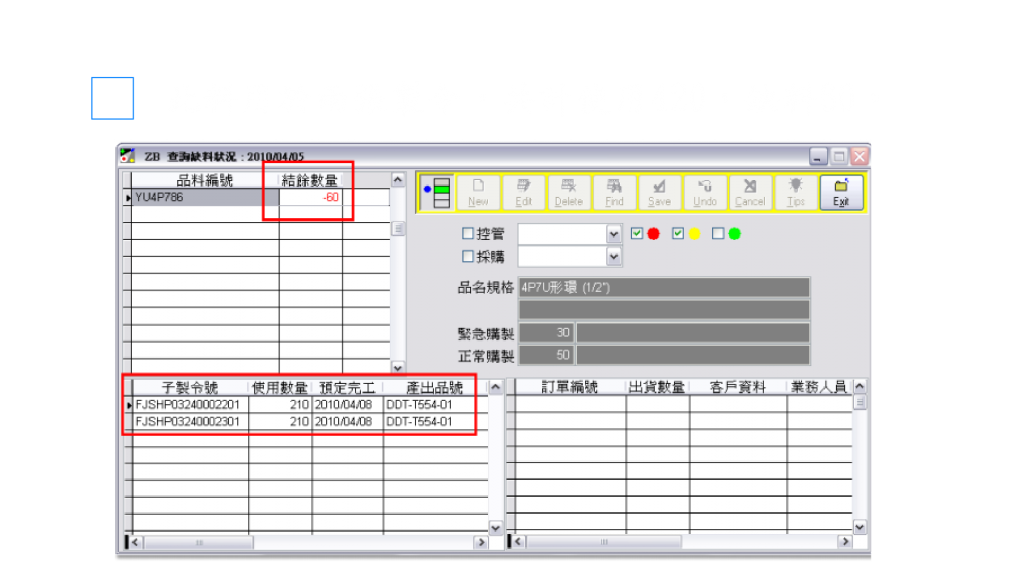

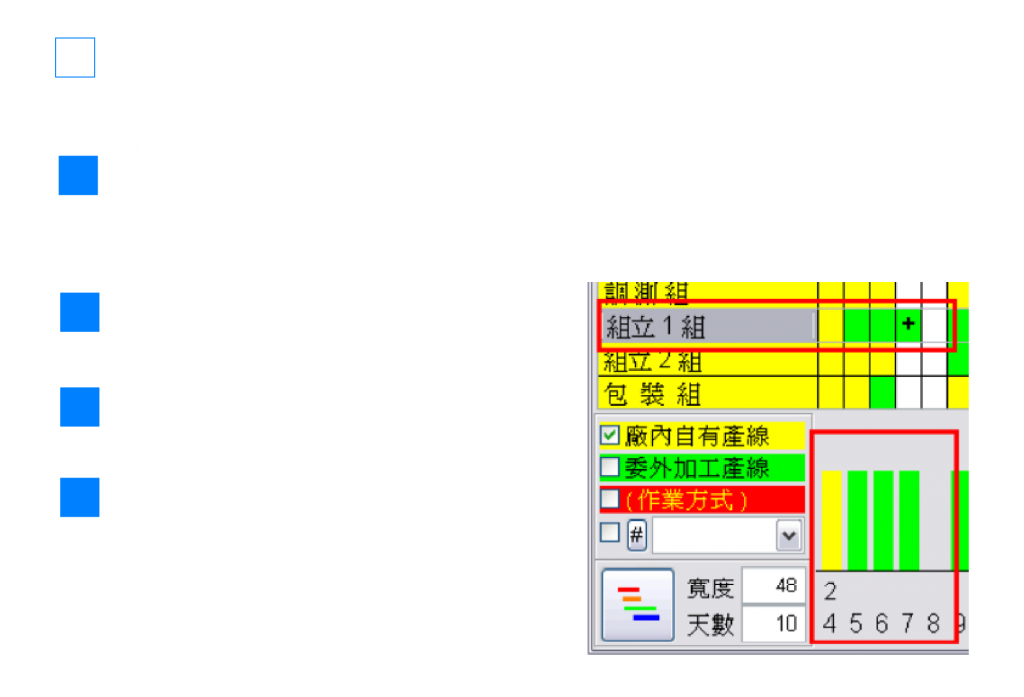

innovated multiple window information on the screen, such as capacity utilization, raw material shortage details, finished product delivery dates, each machine work load status, etc. also shown by different color for critical information, could be learned quickly by new users.

4

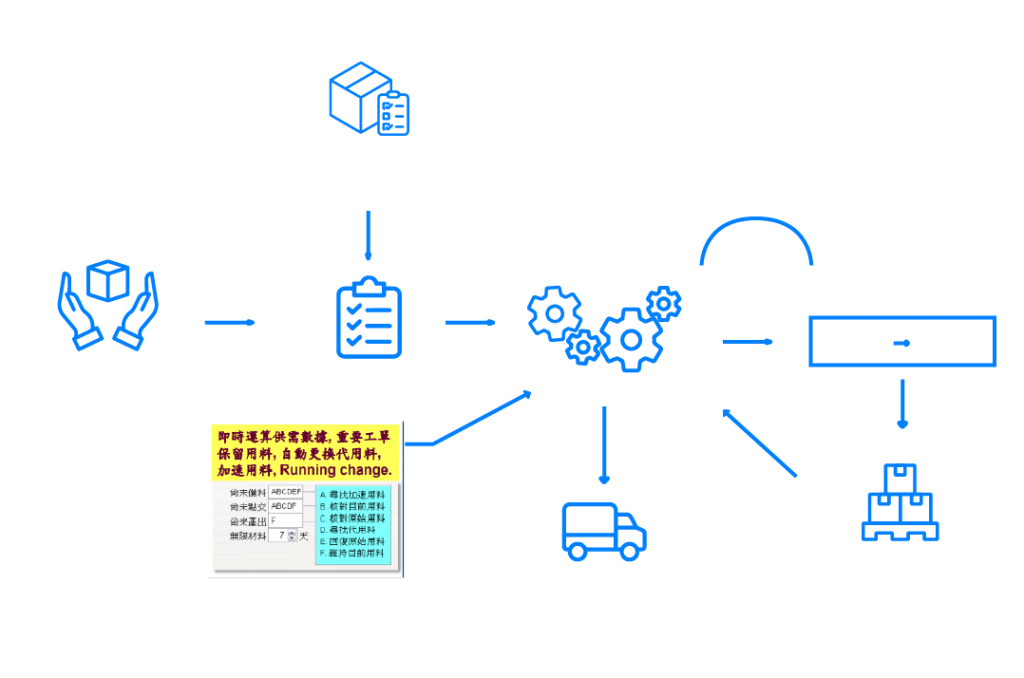

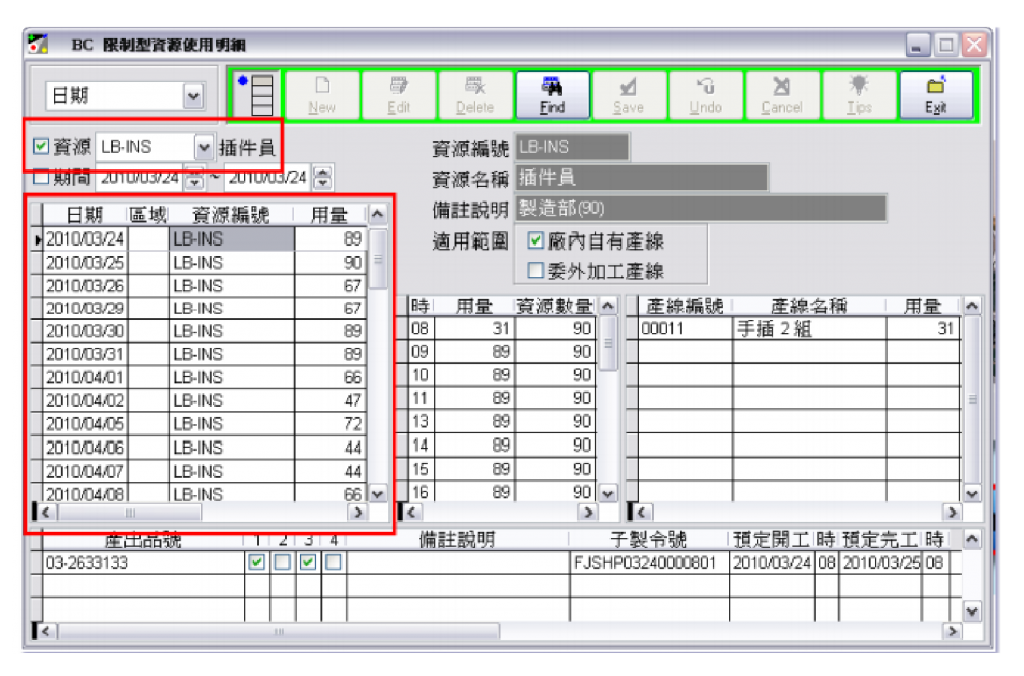

In calculating machine capacity, material, technician, online inspection, multiple production ingredients, APS generates the best planning and scheduling. Also could dynamically reconcile the in-time machine speed changes, for a balanced production planning and scheduling outcome.

5

available to promise(atp)

The APS System has a real time data calculation from the Sales Dept. promised order to Production real operation for meeting the order. Make the Sales people to be more confident for sale order commitment.

6

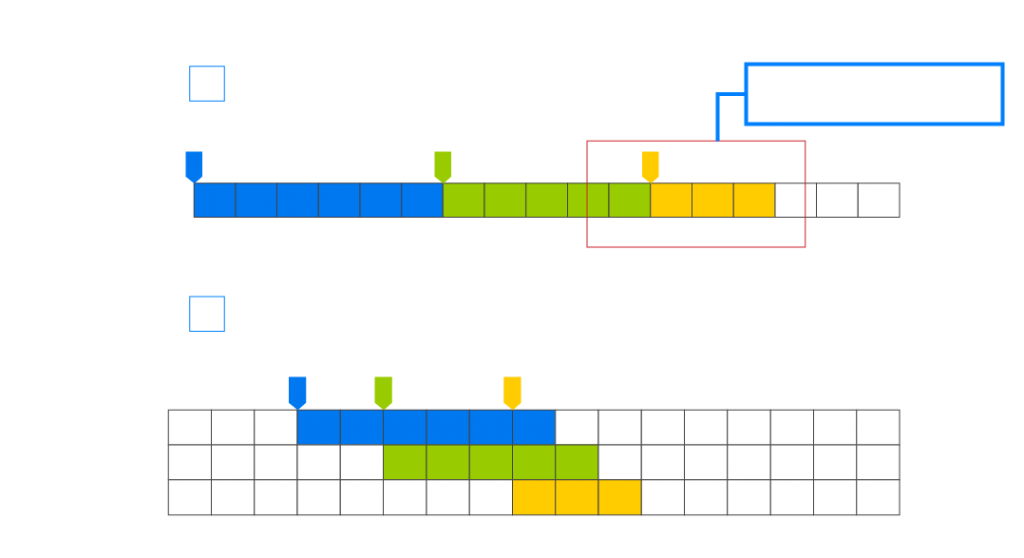

The APS System could be rescheduling any time or designated time, always could have four (4) simulation output for the planner best evaluation the decision making between Sales and Production teams.

7

Other comprehensive parameters included in the APS System:

我是文字標題要置中保留的文字

1. Overtime / Shift Change / Production support / Outsourcing

2. Balancing among all machine / Seasonal factors consideration

3. Peripheral line to follow main production line factor

4. change over loss calculation

5. transportation time between each machine

6. product spec restriction defined at each machine

7. Available to promise sales order set up

1

Spotlight APS is the most advanced product adopted and proved by many listed companies, for securing the success of the application, during the Prove of Concept (POC) time, input the real data for confirming the real effectiveness and value, before make the purchase decision.

2

the aps include external oem or outsourced factory factor for overall calculation, without complicated routing table data, then can generate maximized planning and scheduling information. based on about 75% package-designed comprehensive functions, could shorten the implementing time, simulation outcome verification for comparing with real demand before official purchase order of aps system.

3

innovated multiple window information on the screen, such as capacity utilization, raw material shortage details, finished product delivery dates, each machine work load status, etc. also shown by different color for critical information, could be learned quickly by new users.

4

In calculating machine capacity, material, technician, online inspection, multiple production ingredients, APS generates the best planning and scheduling. Also could dynamically reconcile the in-time machine speed changes, for a balanced production planning and scheduling outcome.

5

available to promise(atp)

The APS System has a real time data calculation from the Sales Dept. promised order to Production real operation for meeting the order. Make the Sales people to be more confident for sale order commitment.

6

The APS System could be rescheduling any time or designated time, always could have four (4) simulation output for the planner best evaluation the decision making between Sales and Production teams.

7

Other comprehensive parameters included in the APS System:

1. Overtime / Shift Change / Production support / Outsourcing

2. Balancing among all machine / Seasonal factors consideration

3. Peripheral line to follow main production line factor

4. change over loss calculation

5. transportation time between each machine

6. product spec restriction defined at each machine

7. Available to promise sales order set up

APS could provide different production plan, for re-simulation, comparison the pro and con of each proposal, to figure out the best plan.

Our served customers

我是文字標題要置中保留的文字

Electronic – Internet device ( SMT / DIP … )

company name: A

installation location: Xindian District, New Taipei City, Taiwan

company products : Internet product (Brand name MOXA)

Production by order or by plan: Production by order with small volume size

Other available software systems: ERP : SAP/MES

Chemical Industry – Powder coating

(Extrusion / crushing)

company name: B

installation location: LinKou District, Taiwan

company products : Powder coating

Production by order or by plan: Diversified small volume order type

Other available software systems: ERP:QAD / Self developed production line bulletin board

CNC Machinery (Lathe / Milling Machine)

company name: C

installation location: KaohSiung District, Taiwan

company products : Aerospace parts

Production by order or by plan: Diversified small volume order type

Other available software systems: CNC Machinery special used ERP/MES

Electronic –

( SMT / DIP … )

company name: Five customers cases application examples

installation location: Taipei

/ Taoyuan / Donguan / Ningbao / Shanghai

company products : Diversified

electronic products (but 5 cases are all different)

Production by order or by plan: First

half semi-products produced by plan, second half finished products produced by

customer orders

Other available software systems: ERP

/ Bar Code / PLM (each case has different situation)

CNC Machinery (Lathe / Milling Machine)

company name: D

installation location: KaohSiung District, Taiwan

company products : SPOT TARGET

Production by order or by plan: Production by order with small volume size

Other available software systems: no other software, only spotlight APS operation

Electronic industry

( SMT / DIP … )

company name: E

installation location: Taoyuan / Donguan District, Taiwan

company products : Family

satellite security system

Production by order or by plan: Produce

by customer orders

Other available software systems: Oracle ERP: 2001 was DOS version, then replaced by OracleKaohSiung District, Taiwan